|

Page 27 I need to follow up on the situation with my fiberglass lined fuel tanks. As you remember the question of epoxy’s ability to handle gas containing ethanol came to light after I had constructed the tanks. To attempt to better understand my situation I decided to run a test on some samples and observe the results. I laid up 2 layers of cloth using the same epoxy I employed in the tanks. Once it cured I used the band saw to cut it into four strips. The day I coated the tank interior with the “Epoxy Gas Tank Sealer” from Caswell I also coated two of the strips. I then dropped 2 strips (one coated / one uncoated) into coffee cans of gas. One of the cans had ethanol and the other did not. This was done on 9/1/00 and the cans were set on a shelf in the garage.

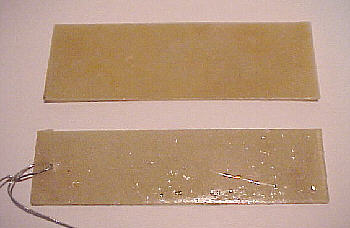

The first photo is of the strips that were placed in the gas with NO ethanol. These strips showed absolutely no damage or change. The color was the same and they maintained their natural stiffness. The straight gasoline seemed to have no affect on the lay-up. (The bottom strip with the gloss finish is the "sealed" strip.)

I also inspected the two solid pieces of sealer I had dropped in the cans. Both of these were in very good condition and showed no visible change. But there was one noticeable difference – the piece dropped in the straight gas had become LESS flexible than it was originally. The piece in the ethanol had stayed about the same as the original or possibly just a little more flexible. So what does all this tell me? That’s a very good question. Obviously the ethanol is causing some problems as both strips suffered some damage. But because of the way it was damaged I wonder if my testing methods were sound. I am very curious as to why only two of the edged showed damage. Actually except for the edges the majority of the strip is still sound (although loss of rigidity points to an overall weakening). Also there has been very little change the past 30 days. The majority of the damage occurred in the first month. When I applied the sealer to the strips I will admit to doing a poor job. The sealer cured very quickly and I just didn’t want to spend too much time messing with these and have the epoxy set before I finished the tanks. There are noticeable areas that did not get sealed well. Did this allow the fuel to contact unprotected surface and cause damage that a fully sealed strip would not have incurred? My guess is yes. And from looking at the piece of solid sealer I think if properly applied it would have protected the sample. Also making these strips by cutting with a band saw was probably a bad idea. I may have opened up the structure and allowed the fuel to more quickly leach down around the glass threads. Since all the damage seems to occur on the edges I suspect this was a contributing factor. But then again maybe it just sped up a process that would have happened any way of a long period of time. So I repeat – What have I learned! Still a good question. I have some answers but in the process created new questions! At this point I am sure I am OK as I have been able to use only gas with NO ethanol. But this could change tomorrow as to how long it will be available is anybody’s guess. If I would have to start using gas with ethanol I am still fairly

confident my tanks would handle it. I gave them a good coating with

the sealer taking great care to get 100% coverage. And so far the

sealer itself seems to be holding up well in the test. Also, if I

would start using ethanol I still have the option of opening the tanks and

checking for damage. If at some point I find a problem I will then

have to decide how to deal with it. Worst case I would make metal

tanks to drop down inside the existing tanks. This wouldn’t be a fun

project and I am sure I will loose some capacity but the CS will still

continue to wander the rivers. For Additional Info On The Ethanol/Epoxy Test Jump Directly To Page 36

|

On 10/1/00 I opened the

cans and inspected the strips. I then put them back. At that

time I also added to each can a solid piece of the “sealer” I had salvaged

from my mixing cups. I allowed them to set for another month and this is

what I found.

On 10/1/00 I opened the

cans and inspected the strips. I then put them back. At that

time I also added to each can a solid piece of the “sealer” I had salvaged

from my mixing cups. I allowed them to set for another month and this is

what I found.

Next I opened the can

with ethanol and removed the strips. This is the one without the

sealer and as the photo shows this strip as suffered considerable damage.

Along two of the edges the resin appears to have absorbed the fuel which

has caused them to curl. The entire strip has noticeably lost some

of its rigidity and by grabbing both ends I can twist it without much

effort. The plys have not delaminated at this point but if it were a

structural member it would definitely be comprised.

Next I opened the can

with ethanol and removed the strips. This is the one without the

sealer and as the photo shows this strip as suffered considerable damage.

Along two of the edges the resin appears to have absorbed the fuel which

has caused them to curl. The entire strip has noticeably lost some

of its rigidity and by grabbing both ends I can twist it without much

effort. The plys have not delaminated at this point but if it were a

structural member it would definitely be comprised.

The strip with the

sealer faired considerably better but still suffered some damage along two

edges. It too has lost some of the stiffness but not to the extent of the

unprotected piece.

The strip with the

sealer faired considerably better but still suffered some damage along two

edges. It too has lost some of the stiffness but not to the extent of the

unprotected piece.