| Another project was adding the keel rollers. I wanted one at the

rear although I don't think it is really necessary. I never plan

on loading it that shallow a situation where I will need to pull the Cabin

Skiff over the rear cross support (the exception maybe loading it on the

trailer the first time at the shop). But you often see these on "factory

trailers" and it will serve as the lower mounting bracket for the "transom

saver" I plan to use on the outboard.

I am also going to add a roller on the next cross member aft of this one. I don't plan on it supporting the hull as the bunks should have it there but I want it to protect the bow from hitting the cross member when loading. I am not sure if this is needed but I do not want to take a chance of scraping the keel on the metal frame.

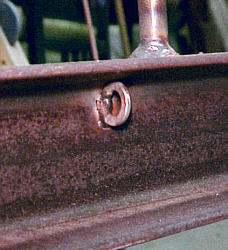

Besides the holes I wanted something to support the wires between the cross members. I decided to weld lock washers under the top flange of the 3" channel. I chose lock washers because they tend to have rounded edges. Flat washers are usually stamped out and are sharp enough to eventually damage the wire. I had considered using short sections of steel tubing welded in place but decided against it because it would be difficult to get paint behind them.

Finally, I drilled all the mounting holes for the lights. If you aren't sure what lights are required you might want to look at this site - Click Here. It list the Federal Lighting Requirements for different types of trailers. With this done I am now ready to prep for painting. I will

need to remove the slight surface rust and wipe the whole thing down.

I am going to wait until the weather is a little warmer and do this right

before I paint. Hopefully I will catch a nice weekend in the

next few weeks.

|

Beside

the rear roller I wanted on at the front to support the bow of the boat.

The 2x4 bunks will not go all the way forward and the roller will carry

the weight of the forward section of the boat. As it worked out forming

the "V" with the front cross member really was not necessary and in fact

worked against me. As you can see in the photo I had to raise the

roller about 7" to meet the keel at this point. I think the height

is accurate but I have only tacked the brackets in place just in case I

am off and need to adjust this. This roller needs to be at the correct

height but I didn't want to go to the trouble of making it adjustable.

If it is wrong I will grind it off and reposition it and re-weld.

Beside

the rear roller I wanted on at the front to support the bow of the boat.

The 2x4 bunks will not go all the way forward and the roller will carry

the weight of the forward section of the boat. As it worked out forming

the "V" with the front cross member really was not necessary and in fact

worked against me. As you can see in the photo I had to raise the

roller about 7" to meet the keel at this point. I think the height

is accurate but I have only tacked the brackets in place just in case I

am off and need to adjust this. This roller needs to be at the correct

height but I didn't want to go to the trouble of making it adjustable.

If it is wrong I will grind it off and reposition it and re-weld.

With

these in place the final project before paint preparation was to prepare

for the lights and wiring. I plan on running the wires down both sides

so I needed to drill holes in the cross supports for them to pass through.

This job would have been much easier if I had drilled these with the drill

press BEFORE I welded them in place. After drilling the 3/8" hole I beveled

the edges on both sides with a 1/2" drill bit to prevent the sharp edged

from cutting into the insulation.

With

these in place the final project before paint preparation was to prepare

for the lights and wiring. I plan on running the wires down both sides

so I needed to drill holes in the cross supports for them to pass through.

This job would have been much easier if I had drilled these with the drill

press BEFORE I welded them in place. After drilling the 3/8" hole I beveled

the edges on both sides with a 1/2" drill bit to prevent the sharp edged

from cutting into the insulation.

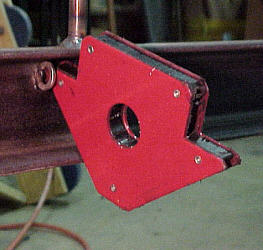

I

used my magnetic welding blocks to hold the washer in place so I could

tack them to the frame. If you don't have a set of these it is something

you should consider. They are about $10 a piece and are extremely

handy when welding.

I

used my magnetic welding blocks to hold the washer in place so I could

tack them to the frame. If you don't have a set of these it is something

you should consider. They are about $10 a piece and are extremely

handy when welding.