Back In The Shop

March 2001

Getting

it in the shop itself was going to be somewhat of a challenge. I want it

to go in bow first and the concrete slab outside the garage door is sloping

up towards the door. To make matters worse, it will only clear the

door if I let all the air out of the tires. This makes it almost impossible

to "push" in by hand. I finally decided that I could use a small

electric hoist I had. By tying it off to anchors set in the concrete floor

I literally dragged the CS in the door. It went very well and only took

a few minutes. (Photos are looking up from the floor) Getting

it in the shop itself was going to be somewhat of a challenge. I want it

to go in bow first and the concrete slab outside the garage door is sloping

up towards the door. To make matters worse, it will only clear the

door if I let all the air out of the tires. This makes it almost impossible

to "push" in by hand. I finally decided that I could use a small

electric hoist I had. By tying it off to anchors set in the concrete floor

I literally dragged the CS in the door. It went very well and only took

a few minutes. (Photos are looking up from the floor)

The main reason I wanted it in the shop was to more carefully survey

the bottom of the boat. As I mentioned earlier I had discovered that I

had managed to build in some upsweep in the aft portion of the hull.

I am fairly certain that is what was causing my bow high situation.

I wanted to see exactly what I had and than try to decide if and how to

correct it.

I

used the hoist to lift off the outboard. I then tied the tongue of the

trailer to the floor and then used my pickup truck to gently pull the Cabin

Skiff back about 2 ft on the trailer. This allowed me easier access to

the bottom without having to work around the bunks. By removing the

engine I could get away with sliding it back this far and not have to worry

about it tipping backwards. Now I was ready to take a straight edge and

tape measure and see what I really had. I

used the hoist to lift off the outboard. I then tied the tongue of the

trailer to the floor and then used my pickup truck to gently pull the Cabin

Skiff back about 2 ft on the trailer. This allowed me easier access to

the bottom without having to work around the bunks. By removing the

engine I could get away with sliding it back this far and not have to worry

about it tipping backwards. Now I was ready to take a straight edge and

tape measure and see what I really had.

Well I did just that and I was shocked! And embarrassed. I

am ashamed to admit what I found because I still can't believe I missed

this much of an error. Running a straight edge along the chine shows

NO problem - everything is flat as it should be. I then ran the line

along the bottom of the transom from the chine to the keel it is also straight.

BUT run the straight edge down the keel and about 18" from the transom

it starts to sweep up and at the transom it is 5/8" above where it should

be. That's 5/8 of an inch off in 18"!!!

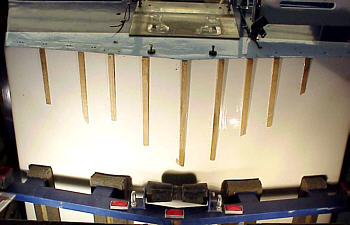

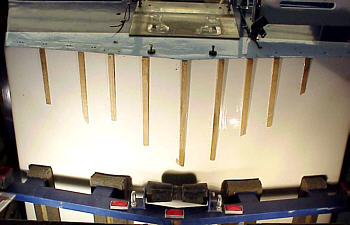

Further

inspection with the straight edge showed that if I start from the mark

on the keel 18" forward of the transom and run to the corners where the

chine and transom meet they are also flat. So what I have is a "V"

shaped area (see top photo) rocking up in what is probably the most

critical area on the hull. I don't know a lot about boat building and/or

design but this can't be good! I still can't figure how this happened but

I am betting it had to do with my method of lengthening the hull by 2 ft

and resizing the transom. Further

inspection with the straight edge showed that if I start from the mark

on the keel 18" forward of the transom and run to the corners where the

chine and transom meet they are also flat. So what I have is a "V"

shaped area (see top photo) rocking up in what is probably the most

critical area on the hull. I don't know a lot about boat building and/or

design but this can't be good! I still can't figure how this happened but

I am betting it had to do with my method of lengthening the hull by 2 ft

and resizing the transom.

I can't live with this - I have to correct it. What I decided

to do is to take strips of hardwood 3/4" wide and cut to the exact taper

needed to flatten the bottom at a particular point. I placed one

of these on the keel and then continue with the next about every 4" to

6" across the bottom (photo is looking up from the floor). These will serve

as "guides" to establish the correct profile. Between these I will cut

and epoxy some less accurate plywood wedges. These will simply be

installed to reduce the amount of epoxy paste needed to fill the void.

I hope this will yield a relatively flat bottom and correct my problem.

At any rate it can't be much worse than it is now!

My

first thought was just to trowel on the epoxy paste as smoothly as possible

by hand but then another builder suggested using a couple pieces

of Formica (with mold release) backed with plywood could be pressed against

the hull and make an almost finished job of it. I dug around the

shop and found a couple of "sink cut-outs" from a kitchen project.

They were about the right size, already had the plastic laminate on one

side and were flat. I cut them to shape with each covering half the area

to be repaired. I decided to do one side at a time so I troweled

on the epoxy paste and then pressed the sheet against the bottom of the

hull. I then wedged a piece of angle iron tightly between it and

the floor which forced the excess out around the edges. My

first thought was just to trowel on the epoxy paste as smoothly as possible

by hand but then another builder suggested using a couple pieces

of Formica (with mold release) backed with plywood could be pressed against

the hull and make an almost finished job of it. I dug around the

shop and found a couple of "sink cut-outs" from a kitchen project.

They were about the right size, already had the plastic laminate on one

side and were flat. I cut them to shape with each covering half the area

to be repaired. I decided to do one side at a time so I troweled

on the epoxy paste and then pressed the sheet against the bottom of the

hull. I then wedged a piece of angle iron tightly between it and

the floor which forced the excess out around the edges.

This worked well. When I removed the sections of countertop

there were a few small voids where I didn't have enough epoxy. Most of

it was very smooth and will require only light sanding to break the glaze

to be ready for paint.

In the last photo the amount of build-up can be seen along the bottom.

Next

Back Home

If you would like to know whenever I update the page

just drop me an email and I will send you a notice.

EMAIL - raymacke@egyptian.net

|

Getting

it in the shop itself was going to be somewhat of a challenge. I want it

to go in bow first and the concrete slab outside the garage door is sloping

up towards the door. To make matters worse, it will only clear the

door if I let all the air out of the tires. This makes it almost impossible

to "push" in by hand. I finally decided that I could use a small

electric hoist I had. By tying it off to anchors set in the concrete floor

I literally dragged the CS in the door. It went very well and only took

a few minutes. (Photos are looking up from the floor)

Getting

it in the shop itself was going to be somewhat of a challenge. I want it

to go in bow first and the concrete slab outside the garage door is sloping

up towards the door. To make matters worse, it will only clear the

door if I let all the air out of the tires. This makes it almost impossible

to "push" in by hand. I finally decided that I could use a small

electric hoist I had. By tying it off to anchors set in the concrete floor

I literally dragged the CS in the door. It went very well and only took

a few minutes. (Photos are looking up from the floor)

I

used the hoist to lift off the outboard. I then tied the tongue of the

trailer to the floor and then used my pickup truck to gently pull the Cabin

Skiff back about 2 ft on the trailer. This allowed me easier access to

the bottom without having to work around the bunks. By removing the

engine I could get away with sliding it back this far and not have to worry

about it tipping backwards. Now I was ready to take a straight edge and

tape measure and see what I really had.

I

used the hoist to lift off the outboard. I then tied the tongue of the

trailer to the floor and then used my pickup truck to gently pull the Cabin

Skiff back about 2 ft on the trailer. This allowed me easier access to

the bottom without having to work around the bunks. By removing the

engine I could get away with sliding it back this far and not have to worry

about it tipping backwards. Now I was ready to take a straight edge and

tape measure and see what I really had.

Further

inspection with the straight edge showed that if I start from the mark

on the keel 18" forward of the transom and run to the corners where the

chine and transom meet they are also flat. So what I have is a "V"

shaped area (see top photo) rocking up in what is probably the most

critical area on the hull. I don't know a lot about boat building and/or

design but this can't be good! I still can't figure how this happened but

I am betting it had to do with my method of lengthening the hull by 2 ft

and resizing the transom.

Further

inspection with the straight edge showed that if I start from the mark

on the keel 18" forward of the transom and run to the corners where the

chine and transom meet they are also flat. So what I have is a "V"

shaped area (see top photo) rocking up in what is probably the most

critical area on the hull. I don't know a lot about boat building and/or

design but this can't be good! I still can't figure how this happened but

I am betting it had to do with my method of lengthening the hull by 2 ft

and resizing the transom.

My

first thought was just to trowel on the epoxy paste as smoothly as possible

by hand but then another builder suggested using a couple pieces

of Formica (with mold release) backed with plywood could be pressed against

the hull and make an almost finished job of it. I dug around the

shop and found a couple of "sink cut-outs" from a kitchen project.

They were about the right size, already had the plastic laminate on one

side and were flat. I cut them to shape with each covering half the area

to be repaired. I decided to do one side at a time so I troweled

on the epoxy paste and then pressed the sheet against the bottom of the

hull. I then wedged a piece of angle iron tightly between it and

the floor which forced the excess out around the edges.

My

first thought was just to trowel on the epoxy paste as smoothly as possible

by hand but then another builder suggested using a couple pieces

of Formica (with mold release) backed with plywood could be pressed against

the hull and make an almost finished job of it. I dug around the

shop and found a couple of "sink cut-outs" from a kitchen project.

They were about the right size, already had the plastic laminate on one

side and were flat. I cut them to shape with each covering half the area

to be repaired. I decided to do one side at a time so I troweled

on the epoxy paste and then pressed the sheet against the bottom of the

hull. I then wedged a piece of angle iron tightly between it and

the floor which forced the excess out around the edges.