|

Next, although

right now the boat will be used in fresh water eventually I would like to

see some salt water time. It is my understanding that steel trailers in

salt water are a poor choice. And finally there is weight. Obviously

towing the boat is going to be a load and my research projected that an

aluminum trailer would weigh about 500 lbs less than a steel unit of the

same size.

Because of these factors I decided I wanted to go with an aluminum trailer. Also on my "wanted list" were torsion axles and LED lights. All my other trailers have leaf springs and they are constantly rusty and squeaking. Plus, since I converted the Skiff's trailer to LEDs I have decided for marine use they are the only smart choice. Also, I wanted brakes on all four wheels. So there was my list of wants and now the job was to find a one to match these criteria.

My first inclination was to try to locate a used trailer as close to my above list. I did locate a couple that were a compromise but workable. But during the search process I decided it would be best if I knew the true weight of the boat rather than depending on the plans projected weight. Because of my modifications I knew I would be heavier but how much heavier was the question. And since the sizing of the trailer is dependent on the length and weight it seemed best not to guess. I sure didn't want to buy a trailer only to find it would not properly support the boat.

So, how do you weigh a boat sitting on the shop floor that will tip the scales at over 5,000 lbs? By having a friend with the right tools, of course! My life long friend and next-door neighbor operates a machine shop and fabricates some rather large assemblies. They sometimes load them on semi trailers and need to know the weight. He has a set of four "highway" scales - the type used by police to set up mobile weigh stations for tractor-trailers. He told me just to come get them.

I set two at

each corner of the transom and two forward on the chine more or less below

the aft edge of the sliding doors. I used floor jacks to lift the boat and

set it back down on the scales. By totaling the four readings I had the

full weight - 5200 lbs (outboard not yet installed). But it also provided

another piece of information that proved to be even more

valuable.

Because I knew the readings on each scale AND the distance from the aft scales to the forward scales I could then calculate the center of gravity. And although I did not yet have the outboard mounted I knew it's weight and distance from the transom so could add it to the calculation for the final dry center of gravity. To my surprise I found the balance point was almost 12' forward of the transom. Why is this so important? In my area most boats in the 27' range are powered with one or two large V8 engines. These present a considerable amount of weight resting very near the transom. As a result most factory trailers have the axles placed far rearward to carry this aft load. Although I didn't run the actual numbers I am sure if I had tried to use one of these "stock" trailers the tongue weight would have been between 1500 to 2000 lbs! I needed a trailer with the axles moved far forward of the norm. A possible solution was to buy a used trailer and move the axles but I was concerned with it not being designed to carry the weight with the axles in that posistion.

Another concern was the bunks. Most planning hulls are reasonably flat in the rear sections of the hull as it approaches the transom. Because of this the normal method is to have two large flat beams serve as the bunks. Because the True Grit is a semi-displacement hull the bottom is a continuous arc - there is no flat surface. This would require a complete reworking of the bunks to fit the hull properly. I called and talked to one of the dealers with one of the used trailers and he agreed. He said he would love to sell me the trailer but was concerned it would just not work out in the long run. Because of this I decided I was going to have to take the hit and have a custom trailer built.

After calling several different trailer manufactures I decided on BoatWheels out of the Cleveland, Ohio area. They are a small shop that does only custom aluminum trailers. I sent them some photos of the boat, the weight calculations and an extensive list of measurements I had taken of the hull bottom. They came back with some very interesting suggestions on how the trailer should be configured. Rather than the heavy flat beams they recommended using a series if post to support four 2x6s laying flat. This would allow them to bend and follow the contour of the hull. They also suggested down the center to place a heavy beam for the keel to rest upon and carry a good portion of the weight. In addition, to carry the somewhat odd weight arrangement they wanted to move to 7" main beams instead of the 6" they would normally use for a boat this size.

All of this made a lot of sense to me and we negotiated a price. It was more than I planned to spend but felt in the long run it was a much better choice. And I am very pleased with it. They build an excellent quality trailer and took the time to address even small features that will make trouble free for years to come. The only real downside was the 1200 miles round trip we had to make to pick it up. But we took a few days and saw the sights around Cleveland and Lake Erie. My wife really enjoyed the Rock and Roll Hall of Fame while I prefered driving along the coast and looking at the lake, the marinas and the boats. Most trailers have large straight bunks like these but it was not going to work in my situation without a lot of modifacation. Note how far back the axles are located.

The bunks on my trailer are 2' X 6" setting flat, which allow them to bend and conform to the hull eliminating any hard spots.

With the Cabin Skiff my wife normally handles all the ramp work. I just climb aboard and she backs us in. But she is somewhat intimidated by the size of SeaQuinn. With the True Grit our normal procedure is for me to back it into the water and then board over the bow. After I back the boat off she parks the truck and trailer (she handles getting the empty trailer backed in when we are loading). In order for me access the bow I fabricated this ladder. It is welded from 3/4" electrical conduit and bolted it to wench and frame. Although strong enough I found the small diameter round steps very uncomfortable on bare feet. My fix was simply to add a piece of foam pipe insulation to each. I cut a bird's mouth in the ends to more or less lock them to the upright and keep them from spinning on the rung. Other than that nothing holds them in place other than the clamping action of the split foam. Initally I had it one step higher but found it would sometimes get hung on the anchor. (NOTE - the foam did not prove very durable and was replaced with a 1" x 2" strips of plastic deck material bolted through the rungs)

Also, a heavy center bunk was added for the skeg that allows it to carry part of the weight while on the trailer. In my opinion, the more the load can be distributed the better.

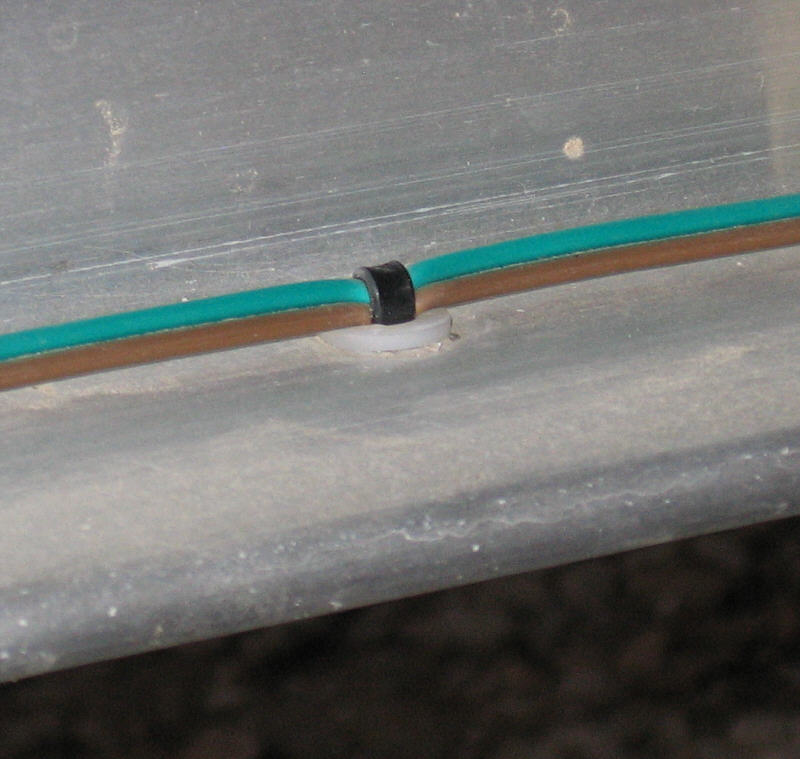

One of the things I liked about the BoatWheels trailer was the attention to detail. Here you a see a very interesting method of securing the wiring. A hole is drilled in the frame member and a plastic insert added. Then a plastic wire tie is threaded up through the hole, looped over the wire and then back down. On the bottom side it is ran through the locking head and tightened . The head of the tie prevents the whole assembly from pulling out. A very simple and clean installation.

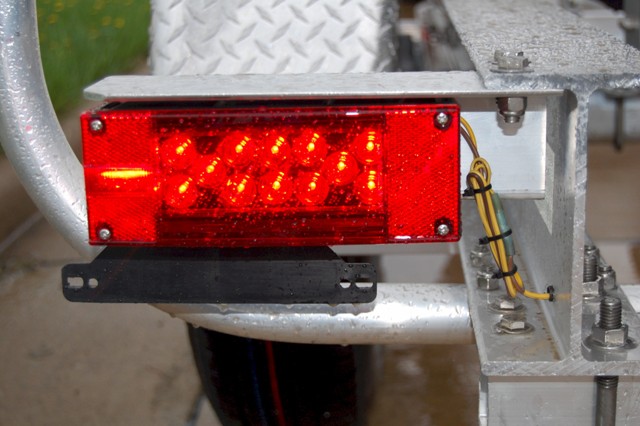

Boatwheels only install LED lights. Note the stainless steel bolts, neat wiring and the grommets used to pass wiring thru the frame.

The fenders are heavy-duty aluminum diamond-plate and solidly mounted. They had nicer wheels available but these worked just fine for me.

The scales were similar to the photo above and would weigh up to 10,000 lbs each. UPDATE It appears Boatwheeels has gone out of business. To bad they built an excellent trailer.

|

Unlike my Cabin Skiff

build, this time I decided early on to purchase the trailer rather than

build it myself. There were several reasons for this. First, I really

don't enjoy working with steel all that much and this trailer was going to

be considerably project larger than the one for the

Skiff.

Unlike my Cabin Skiff

build, this time I decided early on to purchase the trailer rather than

build it myself. There were several reasons for this. First, I really

don't enjoy working with steel all that much and this trailer was going to

be considerably project larger than the one for the

Skiff.