|

We now have about 90 hrs, 500 miles and have spent 18 nights on SeaQuinn. This is not a great deal of time but still enough experience to form an impression about various items. It must be mentioned that I may well be seriously biased but still I will try to be objective.

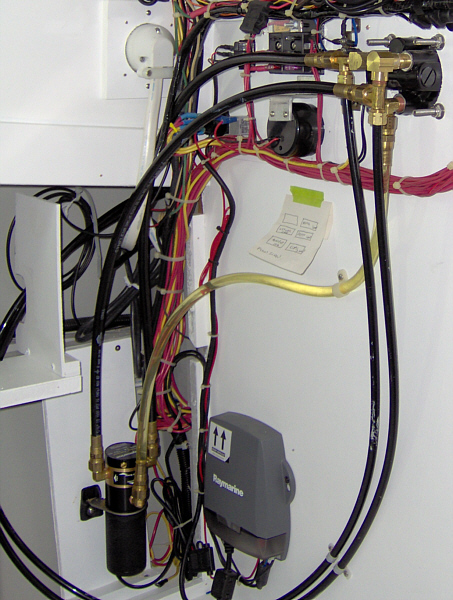

To date one of the biggest revelations is how well everything seems to work. Please don't view this as a boast as that is not the intention. No one is more surprised about this than me! Compared to my Cabin Skiff this is a very complicated build. With a dual electrical system, fresh water system, fuel system, the propane system, hydraulic steering, autopilot, general saloon layout, refrigeration, stand alone shower, composting head, windlass and more that each had to be planned and installed in a 27' hull. With so much going on it a tight area I was prepared for a whole host of things that would probably need tweaking and changing once actually used. But to my surprise there have been few.

In retrospect I feel there are several reasons for this. One is that I took my time with the build. Yes, in the past five years I have spent MANY hours working on the boat but this was my choice of entertainment. There never was a deadline or schedule as it would be done when it was done. Because of that I was free to get things the way I wanted them with little concern for the hours needed. Often it was not the most constructive use of time but I honestly didn't care. Admittedly, there were times I would have to remind myself of the lack of timetable. This was especially true when coming to the conclusion something I had planned and built just wasn't going to work out. It would just have to be scrapped and all the time lost. I would have to repeat to myself that there was no deadline so it didn't matter.

Another benefit of the lack of a schedule was it allowed me more time just to think about the project and sort through the complexities. And for me this is one of the most satisfying elements of building a boat - solving the problems. It is extremely gratifying to confront a situation with no idea of how to resolve it and then work your way through to a reasonable solution. In my life I have built a lot of different things but nothing approaches boat building when it comes to providing this type of satisfaction.

Also, a huge help was my experience cruising with my Cabin Skiff. The many hours I have spent at its helm allowed me to develop a sense of what I wanted in a long-range cruising boat. As I have stated before the Skiff is an excellent craft but Spartan in accommodations. A benefit of this minimalist approach is it has taught me not only what is important and what would make things more comfortable but also what is not necessary. I think this experience helped me develop a more practical boat for my personal style of use.

But so much for theory, let's discuss some of the features that worked and some that didn't -

The Composting Head Lets start with the head. I tend to get a lot of odd looks when I mention there is a Composting Head installed.

For those not familiar with the system, a composting head has no conventional holding tank that must be pumped out. The base of the unit holds about 2 gallon of moist peat moss and the solid waste falls into it through a trap door type arrangement into it. A manual crank on the side of the head is rotated a few times to mix the waste with the peat moss. Once in the chamber and mixed a chemical reaction takes place and the waste is broken down into "compost". This is a similar process to composting yard or food waste at home. With this particular head - Natures Head - the liquid waste is automatically separated and drains into a plastic 2.2 gallon container in the front of the unit's base. The idea is to remove the tank when full and dump in a toilet at a marina or such. The tank does have a carrying handle and a screw on cap for preventing spills. It also is translucent so the fluid level can easily be monitored. But this is an system I feel needs more time before I offer a solid opinion as we just don't have enough working experience with it yet. With that said, I will offer a few preliminary thoughts. So far we have been amazed by the lack of odor. If you do bend down and try to smell it (yes, disgusting but I had to know) there is a smell omitted similar to freshly turned dirt - like digging in the garden. It is not offensive at all. A small 1 5/8" 12v fan (40mm computer CPU type) runs continuously and is used to vent this outside the hull through a 2" hose. We have never smelled it outside or inside the boat. We were surprised at the amount of liquid waste generated by two adults - not something I ever stopped and measured before! We have found if it is the sole method of handling the liquid waste two adults can filled the 2.2 gallon tank in a 24-hour period. We honestly were shocked - had no idea that much is generated. Fortunately additional tanks are available. I will add this was discovered during some very hot weather and I know our consumption of fluids were higher than normal. This may have aggravated the problem but still it appears it will fill rather quickly.

A problem we have encountered is regulating the amount of paper going in. The solid waste themselves don't seem to be a problem but the paper breaks down at a much slower pace. We need more time to see what we can work out. I have a possible solution but want to reserve offering it until we have more experience to see if it is viable.

Beside the head we keep a plactic spray bottle filled with tap water. After usage rinsing the bowl with a few squirts of water is all that is usually needed..

Overall we are pleased with the head. We had a conventional manual flush head in previously owned Express Cruiser and hated it. I think even with the worst-case scenario the composting head will be a vast improvement.

The Outboard

One of the biggest decisions made during the build was the choice of power. As I discussed in an earlier page the Honda 60 Power Thrust (BFP60) was chosen. Now that we have some experience running with it I will say I feel it was a good selection. My goal was fuel economy and I had no interest in attempting to push the hull to plane. I was looking for displacement speeds and perhaps a little more if needed on occasion. We are running a 14" x 8" stainless steel prop made by Power Tech. In fact, this was the only 8" pitch prop I could find and anything more than that was too much and would lug the engine. I could have gone with a smaller diameter but I felt some efficiency would be lost. Common consensus seems to be when moving at slow speeds the bigger the diameter the better. I am still not sure I have the fuel flow gauge 100% accurate but here is what I am seeing at this point. I normally cruise at about 7 MPH which yields a gallon per hour or 7 MPG.

REVISED Numbers as of 9/2014 with increased operating weight and better calibrated fuel flow meter Actual yield maybe 2 1/2% error less than these.

The Blinds

Autopilot

When building any boat there always seems to be two list. One of them is the list of things you "need". These are the items you must have to complete the project. Then there is the list of things you "want". No, they are not mandatory but by conceived calculation or justification the desire is there. And the bigger the boat the larger both list BUT it seems the "want" list grows exponentially compared to the other.

One of the items on my "want" list was an autopilot. My justification was with the slower cruise speed I would not have to sit with my hands on the wheel at all times. I reasoned there are many times when cruising rivers the heading is dead straight for five or more miles. At my projected cruise speed that represents 45 minutes holding the same course. Why not sit back and relax and allow it to make the hundreds of small course corrections needed.

This was a great rationalization of the purchase and all was well until I priced autopilots. I was shocked to find the cost could easily be $3000 to $4000! Definitely out of my range. But still I wanted one. Then I ran onto the Raymarine SmartPilot S1000. I is a little different than the other systems I had found. Instead of having its own internal electronics package to establish headings the S1000 is dependent upon data output from a GPS. Since I would have a GPS it seemed logical to let it serve double duty in this manner. Also, instead of an in-panel control it used a small handheld wireless remote (a bracket was included for attaching it to a surface). From the description it sounded like what I wanted AND the online price was about $850. Still it was a lot of money but within my acceptable range.

There was a problem though - it is advertised as being for boats 25' and smaller and I was going to be over that at 27'. I decided to call Raymarine and ask a few questions. The tech I talked with was fairly adamant about the 25'. I asked what would happen if installed on a larger craft. He said in heavy conditions the unit would be over taxed trying to maintain a heading and would eventually fail. I informed him I was looking at it for use on rivers - not open water- and conditions there are usually less severe. He perhaps gave in a little but still stated it was not a good idea. I persisted with questions and finally he asked the dry weight of the boat and I replied about 5500 lbs. With that he paused. He then stated many 25' boats the units are installed on weigh more than that. After a moment of thought he relented and said it would probably not be a problem. He suggested if I decided to go that way and encountered rough water it still could work the unit hard. The simple answer then is just to switch it off and not use it in those conditions.

For me that was just fine. I wasn't looking for rough weather service rather the opposite. If the going gets tough I prefer to have the wheel myself. I want it to handle the 95% of the time when I just want to relax and watch the shore go by.

So the S1000 was purchased and installed. So far it has worked well. I can just pick a heading and set it to follow it or have it track a route set in the GPS. Either way it tracks very close to the plotted line. The rougher the water the more the pump works and it does produce some noise in the process. This is probably more noticeable for us since the boat is so quiet on the interior but still it is not loud enough to be annoying.

To date the longest single leg it has handled was a seven-mile run. This means we cruised for an hour and I never touched the wheel. Just sat back at the helm, had lunch and let it handle the grunt work. Sweet!

Propane Refrigerator

I know, I know - in the eyes of many propane refrigerators are forbidden in boats. The gas is heavier than air and will settle and build up in low areas. I find it interesting that the role of propane in boats has changed over the years. First, there was a total ban - NONE ALLOWED. Then after years of dealing with the hazards and stink of alcohol, diesel and wood stoves for onboard cooking, some insane boater tried propane - and it was good..... Soon some of his friends noticed the convenience and they too tried it - and it was good. Slowly the experts came around and decided if properly installed propane would acceptable for cooking only - nothing else.

Then another insane boater tried it for cabin heat - and it was good. Yada, yada, yada - you get the idea. Now it is acceptable for cooking and heat but still not for refrigeration. The current logic is for heat and cooking you turn on the gas, complete the task and then turn off the gas. This "lowers" the chance of a leak accumulating large amounts of gas. ( I am sure no one leaves their heater on for long periods of time). With a refrigerator the gas must be left on all the time - increasing the risk. I get it. But I am still not sure what to do with the propane furnace and water heater in my basement. Can't gas build up down there! Turning the gas of and on every time I need heat seems a little inconvenient!

Obviously, the answer is to install a system that checks for gas buildup and if found automatically shuts off the supply. These are readily available and reasonably priced. I would not have the propane system in a boat without one. Plus, from what I have read it seems most all of the disastrous propane problems found on boats are the result of poor installation, poor operation, poor maintenance or any combinations of such. I personally feel if done correctly it can be used safely and effectively onboard.

Why would I want a propane refrigerator? If you are asking that question you obviously have never tried to spend a week on a small boat with an electric refrigerator. I have and it is a constant pain in the transom. To make it work you need big batteries and a generator you don't mind running for hours every day. That's fine if you have the space and money for all and don't mind listening to the generator drone on and on. But it is just not what I wanted to do.

I did some digging on the Internet and found there a lot of boaters that for years have cruised many miles with propane refrigerators. Author "Skipper Bob" was a firm believer in this and did so for 44,000 miles with no problems. In my opinion some in the near future the experts will finally come around to accepting it too. But I decided I am not waiting.

As I mentioned before we don't have a lot of time on the boat but so far the Norcold N510 has worked flawlessly. And why shouldn't it. They are installed in thousands of campers and motor homes worldwide. There is a possibility of trouble if they are not level when operated. This could be a problem in a sailboat that remains heeled for hours on end. But in most powerboats it seems not to be an issue. I see my trawler as no different than a motor home in this respect as they rock and roll as they run down uneven roads.

For me a propane refrigerator is currently the best solution.

The Propane Locker

Along with a propane refrigerator comes the need for a propane locker for storage of the tanks. The ABYC has very clear requirements for these and I wanted to comply for the obvious safety reasons. Commercially built lockers are available but the size I would need was over $800. I decided I could build one for much less. The lockers need to be air tight with a lid that latches. All lines exiting the locker must be near the top of the locker and installed to maintain the seal. The locker is also required to have a vent at the bottom and it must exit outside the hull. The idea is if there is a leak the heavier than air gas will flow to the bottom of the locker and then out of the boat. Otherwise it could pool in a low area somewhere and be a serious explosion hazard.

Making the chamber air tight with a sealed lid was not a problem but the overboard vent present a challange. The way I needed to situate the locker prevented it from sitting very high in the cockpit. As a result, if I just drilled a hole in the hull side for the vent I was afraid any good size waves would wash into the locker. No type of scupper can be used to hold the water out as it might well hold the gas in - defeating the whole purpose of the vent.

After a lot of thought I decided to fabricate a channel and actually extend the vent line through the locker floor down and then make a 90 degree turn allowing it to exit just a couple inches above the waterline. Why did think moving it "closer" to the water line would help? This was my reasoning - if I create a narrow passage way the water would have to enter the 1/2" vent hole in the hull side, make a 90 degree turn and then force it's way up the tube. Since the locker is air tight the water would have to overcome the air pressure building in the locker. This air lock "should" prevent the water from traveling very far up the vent tube. Sort of like taking a drained garden hose and attaching it to a closed faucet and then trying to blow a mouthful of water in it from the open end. The water may go up a little but it isn't going far - at least that was my theory!

I am pleased to say in practice it has worked out. We have had some large wakes hit the side as well as the boat roll a good amount and have yet to have any water in the locker. I know the waves were higher on the hull than the bottom of the locker so the airlock created does seem to work.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||