Our

fourth season using the True Grit brought about an

unusual problem. When not in use it is parked on the trailer under roof

at my

home, which is located in a heavily wooded area.

Southern Illinois has hot humid summers and the

wooded location

helps with the heat but increases the humidity. To prevent mildew I

keep it

closed up and run a small dehumidifier inside – an action that has

successfully

kept the fungi at bay. Because I have a gas heater and gas refrigerator

installed, I also have a Carbon Monoxide (CO) monitor/alarm mounted in

the

cabin.

The problem presented itself a couple days after a four-day

outing. I climbed up in the boat and the CO alarm was screaming and

it’s LED

readout showed a fairly high reading. This was curious because there

was no

source of CO in operation. I opened it up the cabin, aired it out and

shut it

up again. I reset the unit but the next day the alarm was again

sounding. I assumed

the alarm was faulty so I

installed a new one but the result was the same – the next day a high

level of

carbon monoxide was detected.

Now

I am totally confused.

How can there be CO with no source? The only items

running in the boat

were the dehumidifier and the battery charger. At a loss for an answer

I

decided to do an Internet search for other possible origins of CO that

might be

the cause. A google search yielded no other CO sources that made sense

but I did find

an interesting article about CO detectors reading the presence of

hydrogen - http://www.usfa.fema.gov/pdf/efop/efo27803.pdf

. Further reading disclosed that most all

electrochemical CO sensors will show a degree of cross sensitivity to

hydrogen.

Additional searches discovered numerous articles where CO detectors

were being

triggered by the charging of lead acid batteries in the near vicinity.

To test this theory I placed the

detector in my house battery bank enclosure (two 6 volt golf cart

batteries)

and with in a minute it was sounding with a high reading. I took the detector

outside for a while

until it read zero and brought it back into the cabin. Again it sounded. I replaced the

battery box lid and then I

opened just the hatch in the saloon roof.

In a few minutes it cleared and the detector read

zero. To me this

proved the gas was lighter than

air and self exhausted through the upper hatch. To me this more or less

confirmed it was indeed a hydrogen problem.

But why now?

The first three seasons I had all the same

equipment installed and had no problems with this.

My understanding is high hydrogen output from lead

acid batteries

is usually caused by overcharging as the result of a defective charger

or a

cell going bad. But charger was performing properly. In fact, I was

getting

this excessive hydrogen when the charger was in just the float or

maintenance

mode and showing a voltage about 13.3.

I then used a hydrometer to check the charge

status on all the

individual cells and found nothing unusual. I check with both the

charger

manufacturer (Xantrex) and the battery maker and neither offered an

advice or

explanation for the excessive hydrogen off gassing.

I will say the highest

reading I

obtained in the cabin was about 80 ppm. If the detector measures

hydrogen

accurately and I am interpreting

the data correctly it does not appear this is

anywhere near 4% level (40,000 ppm) to be an explosion risk. But I could never find

information on the

safe level to inhale lower amounts over a long period of time. I

decided the

best course of action was to improve my battery box seal and venting

system to eliminate

the unwanted gas.

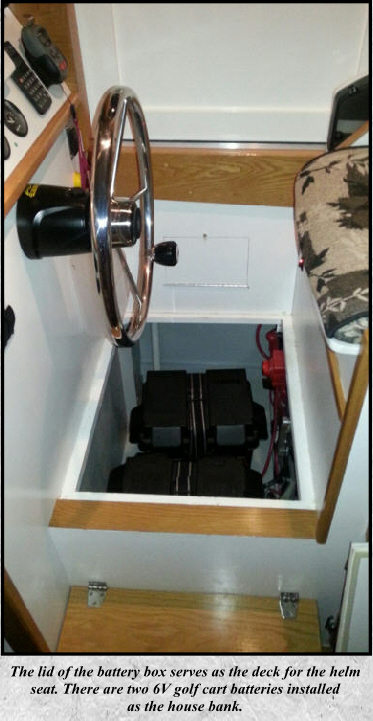

When I built the enclosure I did

include a single 7/8" hole near the top of the box. On the outside it

is

covered with a small stainless steel clamshell and behind it a piece of

screen

wire to keep out the wasp. I

also was

careful to seal the enclosure’s edges/corners and any penetrations. The

top of

the box was simply a piece of 1/2” plywood set into a recess to hold it

in

place. There

was no gasket or seal just

a nice fit with gravity holding it down. This is actually the deck when

sitting at the helm.

When I built the enclosure I did

include a single 7/8" hole near the top of the box. On the outside it

is

covered with a small stainless steel clamshell and behind it a piece of

screen

wire to keep out the wasp. I

also was

careful to seal the enclosure’s edges/corners and any penetrations. The

top of

the box was simply a piece of 1/2” plywood set into a recess to hold it

in

place. There

was no gasket or seal just

a nice fit with gravity holding it down. This is actually the deck when

sitting at the helm.

My first attempt at a solution was

simply to add a foam weather strip type gasket to improve the seal. Testing found it might

have slowed down the

process a little but still the hydrogen was escaping. Next, I decided

to try to

improve my passive vent system. I

added

a second hole through the side of the hull - one would serve as an

intake the

other an exhaust. Since

I wanted both

of these to remain high on the hull to prevent water intrusion I added

a 1”

plastic tube to serve as a duct routing the intake air to the bottom of

the

box. The new hole was added for the exhaust and was placed as high in

the

enclosure as possible. The

idea was the

lighter than air hydrogen would escape the upper hole creating a slight

vacuum

that would pull fresh air down through the tube to the bottom. In

theory this

should work but reality often tends to ignore good theories. The gas

buildup

continued.

Finally, I decided to abandon the

passive vent idea and go with power. I honestly didn’t want to do this

as it

adds additional draw on the battery (however small) and provides

another device

which I know will eventually fail. But I wanted the hydrogen

eliminated, as I

just didn’t like the idea of it being present even in low level

amounts.

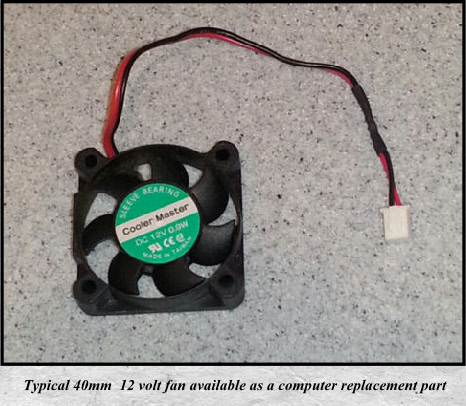

Since I knew the amount of air transfer needed to keep the box clear would be minimal I decided on the smallest 12v fan that was easily obtainable – 40mm. These are very inexpensive and since they are brushless motors there is no chance of causing an explosion. An added benefit was my composting head uses the same fan for ventilation so I always carry a couple onboard as a backup. The current draw is negligible at about .9 watt or .075 amp.

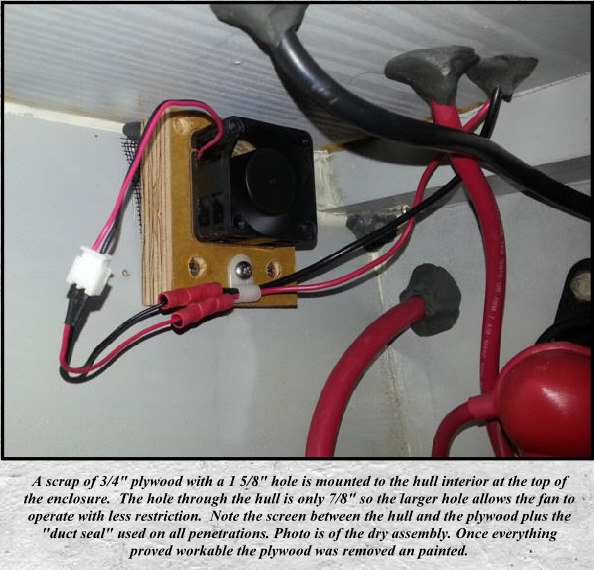

I simply made a mounting plate out

of 3/4" plywood with an 1 5/8" hole for the fan. It was glued to the

interior of the hull, centered over the

existing hole with two screws then hold the fan to it. This allows easy

removal

and replacement when needed.

I simply made a mounting plate out

of 3/4" plywood with an 1 5/8" hole for the fan. It was glued to the

interior of the hull, centered over the

existing hole with two screws then hold the fan to it. This allows easy

removal

and replacement when needed.

The biggest hassle was the wiring,

as I wanted a separate fuse and switch to control the fan. Plus, I did not

want an inline fuse but

rather utilize and existing open slot in the 12v fuse block. Not only

does it

make a cleaner install but moves the fuse outside the battery

enclosure. I am

fairly sure the ATC fuses I am using are not sealed and the arc created

when

one blows could have serious consequences in a possibly high hydrogen

environment inside the battery box. The switch was located below the

helm seat,

which is also outside the battery box and has an indicator light to

note the

fan is in operation.

To date the fan seems to have

solved the problem as in storage I have yet to see even a small reading

on the

CO detector. When the boat is in use we normally have windows and

hatches open

so I don’t run the fan as the gas is readily dispersed.

If the weather was colder and we have things

closed tight I will simply run the fan to keep the fumes at bay. In

storage I allow it to run continuously.

I honestly wish I had been able to get a passive system to work but

this solution

is frugal in both cost and energy so it is a compromise I can accept.

Still

I am curious as to why this

problem didn’t present itself until the fourth season of use. If anyone

has a

though or knowledge on this, please drop me an email. I really would

like to

better understand

the situation.

UPDATE

During

the 2014 season this situation only presented itself once. And that was

during hot weather. Other that that I have not been running the fan

during storage and have not been seeing any hydrogen buildup.

Still totally baffled as to what sets this off at times.